Industrial Equipment Replacement

Air House & Regenerative Thermo Oxidizer (RTO) Replacement Project

Background

- Customer/Location: Paint facility located in West Michigan

- This paint facility is primarily an automotive-based tier 1 supplier and was facing a dilemma. The dilemma was knowing that replacement of their aging HVAC & RTO system was badly needed, but downtime available was very limited due to an extremely high production demand.

- Throughout the budgeting and design process, production continued to ramp up, which meant the allowable downtime continued to shrink.

- The original downtime shrank from 3 months, to 2 months, to 2 weeks, and finally to just 9 days.

- Due to the above time constraints, a total re-design was incorporated to perform the following:

- Install a single structure/stand next to the plant

- Install a mechanical room at the base of the new structure

- Demolition of existing regenerative thermal oxidizer (RTO)

- Install a new RTO

- Installation of (6) new Air Houses

- Demolition of existing Air Houses

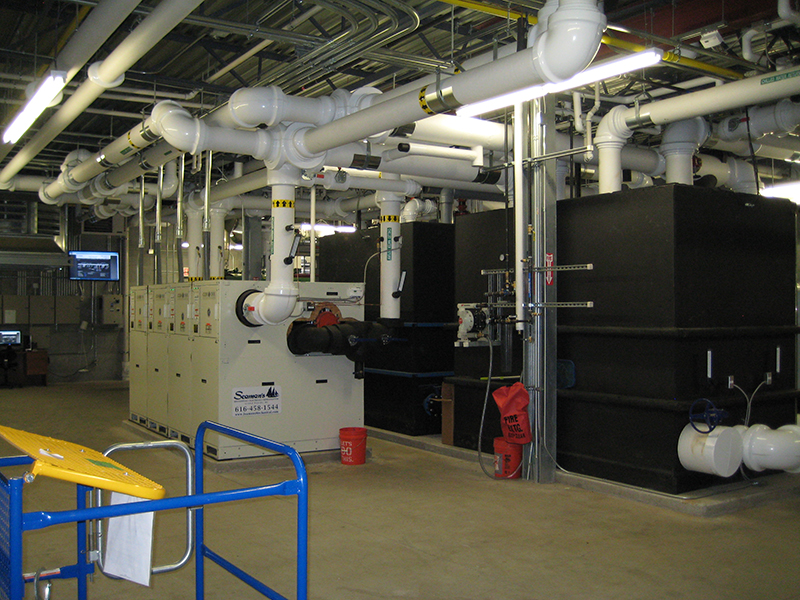

- MEP installation inside mechanical room

- Energy Management Controls

- Replacement of roof-mounted exhaust fans and stacks

- Duct across the roof

- Plumbing of mechanical room and mechanical room equipment

- Nine day change over to new system including the demolition of existing

Objective

Upgrade the system to meet the new design parameters of 70°F at 70% Relative Humidity for all units and zones, including as basis for Humidification for 100% Outdoor Air units.

Equipment

- Recirculating Air House:

- Booth #1 › 60,000 CFM Design basis

- Booth #2 › 60,000 CFM Design basis

- Booth #3 › 40,000 CFM Design basis

- 100% Outdoor Air House

- Booth #1 › 30,000 CFM Design basis

- Booth #2 › 30,000 CFM Design basis

- Booth #3 › 40,000 CFM Design basis

- 340 Ton Heat Reclaim Chiller

- 390 Ton VFD Screw Chiller

- 150 H.P. Humidification Boiler

- RTO

- RTO Heat Reclaim Coil

- 13 Pumps with VFD's

- Energy Management Controls

- Cooling Tower

Results

- Completed the project in 8 days!

- Product First Time Thru (FTT) rate improved on day one

- Elimination of Boiler System previously required for heating

- Increased quality of product

- Greatly improved system control

- And much more!